No products in the cart.

Industrial Electric Stirrers

Our laboratory electric overhead stirrers and mixers feature a totally enclosed non-ventilated mechanical motor that keeps dust and corrosive fumes out for a longer, more trouble-free service life. These overhead electric motorized stirrers allow for easy electronic regulation of the mixing speed and all models are built with overload protection.

Our industrial electric mixers & stirrers also come equipped with an enclosed control box which safely guards vital components from corrosive splashes or spills. All electric stirrer models come standard with an aluminum support rod, a three wire cord with grounded plug, and a 316 stainless steel shaft and propeller which resist most acids and chemicals. As experienced industrial stirrer manufacturers, we have a wide selection of professional mixing equipment below you can check out. Find the perfect overhead lab mixer for your business by reading our buyer’s guide to learn more about what mixing stirrer is best for you. You can also check out some of our other top products such as our air powered mixers and stirrers any time on our site.

FAQ’s

What is an electric overhead mixer used for?

A: An electric overhead mixer is used to blend, stir, or homogenize liquids and semi-solids in lab, industrial, and production settings. Arrow’s mixers handle everything from light solutions to high-viscosity materials, making them ideal for chemical, food, cosmetic, and pharmaceutical applications.

How do I choose the right electric mixer for my lab or plant?

A: The right mixer depends on viscosity, batch size, and RPM needs. For thin liquids, high-speed mixers like the Model 1750 (2,000 RPM) work best. For thicker materials, geared mixers like the Model 350 provide more torque. Batch volume also matters—smaller containers require compact mixers, while larger tanks need higher-power models.

What accessories do I need with an electric mixer?

A: Standard mixers come with a stainless-steel shaft and propeller, support rod, and grounded power cord. Depending on your setup, you may also need a stand, clamp, or different propeller designs to fit your container and material. Accessories like PTFE-coated parts are available for corrosive applications.

What size batches can an industrial electric mixer handle?

A: Arrow’s industrial electric mixers can handle anywhere from small lab volumes (under 20 liters) to larger production batches (up to 100 liters), depending on the model. Torque, RPM range, and propeller size determine the best fit for your process.

How do I Select the Right Electric Mixer Model for my Batch Size and Viscosity?

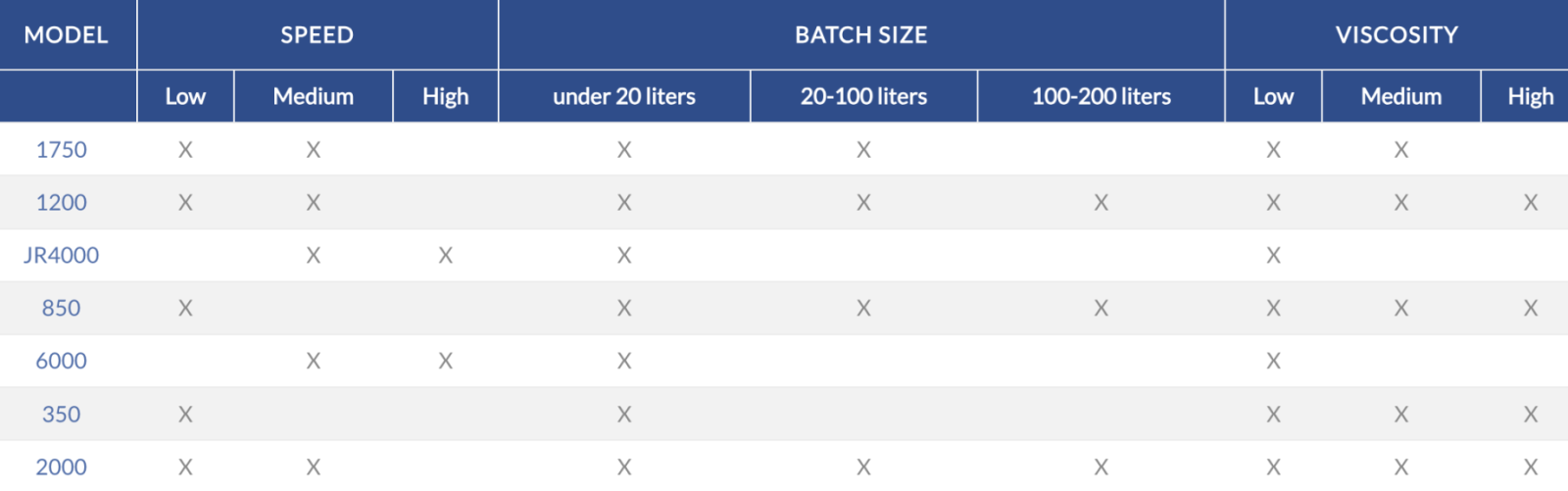

A: Batch size and viscosity are the most essential starting points. Here’s a quick breakdown of models based on the size and type of mixture you’re working with:

- Small Batches (Under 20 Liters): Choose from Models 1750, 1200, JR4000, 850, or 6000. These are perfect for benchtop labs or compact containers.

- Medium Batches (20–100 Liters): Models like the 1200, 850, 350, and 2000RV (digital) handle mid-size processing with ease.

- Larger Batches (100–200 Liters): Go with Models 1200, 850, or 2000RV (digital) for the power and shaft length needed in bigger vessels or drums.

- High Viscosity Materials: If you’re mixing heavy compounds like adhesives, slurries, or thick emulsions, use Models 1200, 850, 350, or 2000RV (digital), which all support high viscosity workloads. The Model 350, in particular, has a 7:1 gear ratio ideal for demanding, torque-intensive mixing.

- Low to Medium Viscosity Liquids: For lighter or moderately viscous solutions, Models like 1750, 6000, and JR4000 provide smooth, efficient operation without overkill on torque.

How Do Motor Speed Options Affect Mixer Performance?

A: Speed directly impacts the mixing quality and air incorporation into the batch:

- High Speed (Model 1750, up to 2000 RPM): Great for light mixing tasks or fast blending of low-viscosity liquids.

- Medium Speed: Available in nearly all models except the JR4000—ideal for everyday lab and industrial tasks.

- Low Speed: Every model except the JR4000 supports low-speed operation, essential for controlled agitation of thick fluids.

What Makes Arrow’s Electric Mixers Ideal for Industrial Use?

A: Every Arrow electric overhead mixer includes:

- A TENV motor (Totally Enclosed Non-Ventilated) to keep out dust and fumes

- A sealed control box that guards against corrosive splashes

- Overload protection to extend lifespan and prevent damage

- 316 stainless steel shaft and propeller resistant to most chemicals

- An aluminum support rod and a grounded three-wire plug for stable operation

These features are designed with rugged lab and production environments in mind—no exposed electronics, no flimsy materials, and no compromise on safety.

When Should I Avoid Using an Electric Mixer?

A: Avoid electric mixers if you’re working with flammable materials. The presence of electrical components creates the possibility of sparking, which poses a safety hazard in volatile environments. For operations involving solvents, alcohols, or other combustible chemicals, air-powered mixers are the safer option, as they generate no sparks and have no electrical current near the mixture.

How Does an Electric Mixer Differ from an Air-Powered Mixer?

A: Electric mixers rely on an enclosed electric motor to turn their mixing shafts, offering near-total energy transfer from the power source to the propeller. In contrast, air mixers use compressed air supplied by an external compressor. While both types offer variable speed options and solid torque output, electric mixers are the more energy-efficient choice, especially in facilities where electricity is more accessible than compressed air.

Can Electric Mixers be Customized or Accessorized?

A: Absolutely. Mixer shafts and propellers are available in different lengths and diameters. If you’re working with corrosive materials, ask for PTFE-coated components. We also offer stands and clamps to secure the mixer—like the SSS-55 stand, which supports 55-gallon drums. Select models like the Model 2000RV feature reversible motors, offering extra control over agitation patterns.

Need Help Matching a Mixer to Your Operation?

Our engineers can help you select the best industrial electric mixer for your specific application. Explore all electric mixers here, or contact Arrow Mixing Products for a personalized recommendation. All mixers are backed by a 30-day guarantee, so you can purchase with confidence.