Subtotal: $754.00

Explosion-Proof Air Powered Stirrers & Mixers

Our air-powered mixers are explosion proof which eliminates the possibility of spark ignition when working with volatile chemicals, solvents, lacquers, and other flammable solutions. This makes Arrow’s industrial stirrers perfect for laboratory use. As one of the top industrial stirrer manufacturers, we offer both reversible and non-reversible air mixers which are capable of handling your high speed, high torque mixing applications.

These overhead stirrers come equipped with a needle valve to control your mixing speed. We recommend using a filter/regulator in your air supply and an air-line lubricator for a long and trouble-free motor life in our pneumatic mixers. Unlike electric models, air driven mixers offer superior safety in hazardous environments where flammable vapors are present. All explosion proof air driven mixers come standard with an aluminum support rod, a four-foot air hose, and a 316 stainless steel shaft and propeller. Built for reliability and ideal performance, these mixers best ensure consistent results in demanding applications. They are designed to meet the rigorous demands of various types of industries. Contact us today to learn more about our available air powered stirrers!

FAQ’s

What is an air mixer (pneumatic mixer/air-powered mixer)?

A: An air mixer – also called a pneumatic or air-powered/air-driven mixer – is powered by compressed air rather than electricity. At Arrow Mixing Products, our air mixers feature explosion-proof construction that eliminates spark ignition, making them safe and reliable for volatile, flammable, or hazardous environments.

Why should I choose an air-powered mixer instead of an electric mixer?

A: Choose an air-powered mixer when working with flammable materials, solvents, or environments where spark risk is an issue. Arrow’s pneumatic mixers provide superior safety (explosion-proof), variable torque (air pressure dynamically adjusts load), and rugged performance in demanding applications. In contrast, electric mixers are more energy efficient but less safe in volatile settings.

Why are Pneumatic Mixers the Best Choice for Hazardous Environments?

A: Because pneumatic mixers operate on compressed air, they eliminate the risk of spark ignition—making them the preferred option for use with flammable solvents, chemicals, and vapors. Arrow’s air mixers are designed to perform safely and reliably in places where electric stirrers simply aren’t an option, such as chemical plants, paint facilities, and fuel labs.

How should I set up my air supply for optimal performance and mixer longevity?

A: For optimum results, Arrow recommends using a filter/regulator in your air supply to ensure clean, consistent pressure, and an air-line lubricator to maintain motor life. Adjustable needle-valve speed control is built into Arrow pneumatic mixers for precise speed regulation.

What are the key advantages of Arrow’s pneumatic (air-driven) mixers?

A: Key advantages include:

- Built for reliability: Includes needle-valve speed control, stainless steel shafts/propellers, and comes with hose, rod, and muffler.

- Explosion-proof safety: No risk of electrical spark.

- Reversible or non-reversible models: Adaptable to high-speed or high-torque needs.

How Do I Choose the Right Air Mixer for My Material?

A: To select the most efficient air mixer, consider these three material properties:

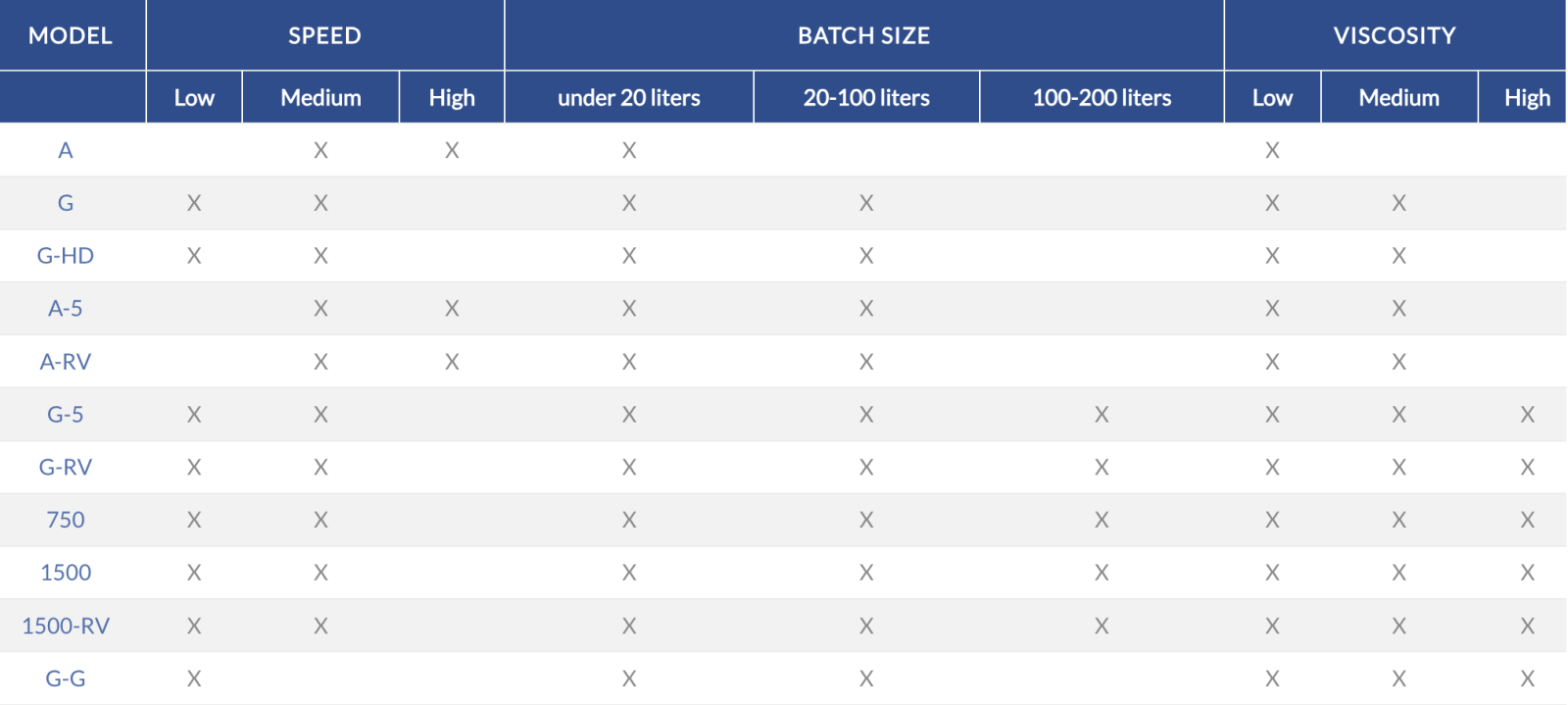

Material Viscosity

Viscosity refers to the thickness or thinness of a liquid. Higher-viscosity materials, such as resins or pastes, require more torque to mix thoroughly.

- For thick, high-viscosity materials, consider models such as the G-5, G-RV, 1500, or 1500-RV.

- Lighter fluids are suitable for models like the A, A5-RV, or A-5, which run at higher speeds and work well with low resistance.

Batch Size

Batch size determines the physical size and the required shaft length. Some examples include:

- Under 20 liters: Consider A, G, G-HD, G-G, or A-5.

- 20–100 liters: Look at G-5, G-RV, G-G, 750, or 1500.

- 100–200 liters: The G-5, G-RV, 1500, and 1500-RV handle large-capacity mixing with ease.

Motor Speed

Air mixer speed is controlled by adjusting the input PSI. Ideal speed depends on your application:

- Need high-speed mixing? Try models like the A, A-5, or A5-RV.

- For medium-speed use, models like the G-HD, G, or 1500 are balanced choices.

- Low-speed operation is found in nearly all models—great for controlled agitation.

What Extra Features or Configurations Should I Consider?

A: Some models come with a reversible function, allowing the shaft to spin in both directions—handy for breaking up settled or layered materials. Examples include:

This feature is great for multi-stage blending or reversing agitation patterns mid-process.

What Accessories or Equipment Do I Need to Use My Mixer?

A: Every air mixer includes:

- A 316 stainless steel shaft and propeller

- 4 ft. air hose

- Aluminum support rod

- Muffler (to minimize noise)

Optional, but recommended accessories include:

- Filter/regulator/lubricator unit – Ensures clean, dry air input and extends motor life.

- PTFE shaft/propeller – For highly corrosive or caustic materials.

- Stands and clamps – Required to secure the mixer, depending on your container type and mixer weight.

What if I’m not sure which Mixer Model is Right for me?

A: We understand that there are numerous options. That’s why we offer personalized support. Simply call us at 1-866-649-6505, and we’ll guide you through selecting a model based on your batch size, materials, torque requirements, and workspace needs. If you have a specialty application, we also offer custom solutions through our in-house fabrication facility.

And don’t worry, all Arrow mixers come with a 30-day guarantee, so if the one you buy isn’t quite right, you can exchange it for a better fit.

Ready to find the best mixer for your job?

Visit our Air Mixers page to explore models or reach out for expert recommendations. At Arrow, we make industrial mixing safe, reliable, and surprisingly simple.

Model G Air Mixer

Model G Air Mixer